What Kind of Canvas is Suitable for UVgel Printing?

Blogs 2025-09-23

In the ever-evolving world of digital printing, UVgel technology has emerged as a game-changer, especially for artists, photographers, and print service providers working with canvas materials.

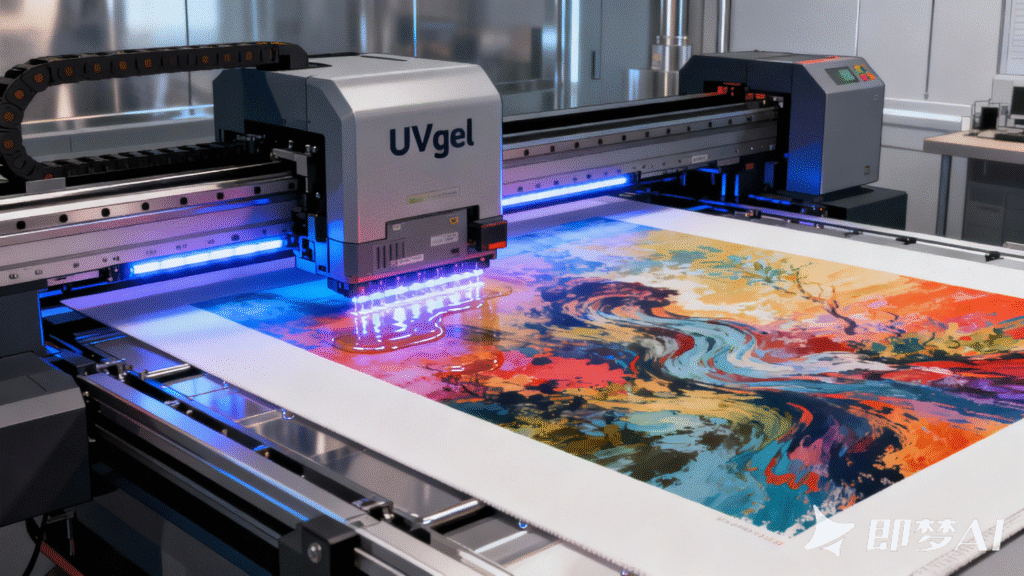

UVgel printing is an innovative, advanced printing technology designed primarily for large-format printing applications. Developed by Canon, UVgel technology combines the strengths of traditional ink technologies, such as eco-solvent, latex, and UV, while addressing their limitations. This cutting-edge approach utilizes a unique gel-based ink that delivers exceptional print quality, high productivity, and versatility across various substrates. UVgel printing is particularly renowned for its ability to produce vibrant, durable prints with precise dot control, making it a game-changer in industries like signage, packaging, and interior décor.

But not all canvases are created equal when it comes to this advanced printing method. In this article, we explore the key characteristics that make a canvas ideal for UVgel printing. Understanding these factors can help you achieve professional results while protecting your equipment.

Understanding UVgel Printing and Its Demands on Canvas

UVgel printing, pioneered by Canon, uses a unique ink that gels upon contact with the substrate before being cured with UV light. This process allows for precise dot placement and minimal ink spread, resulting in sharp, high-resolution images on canvas. However, the technology’s printheads operate very close to the media surface—often just millimeters away—to ensure accuracy. This proximity means the canvas must meet specific standards to avoid issues like head strikes or uneven ink application.

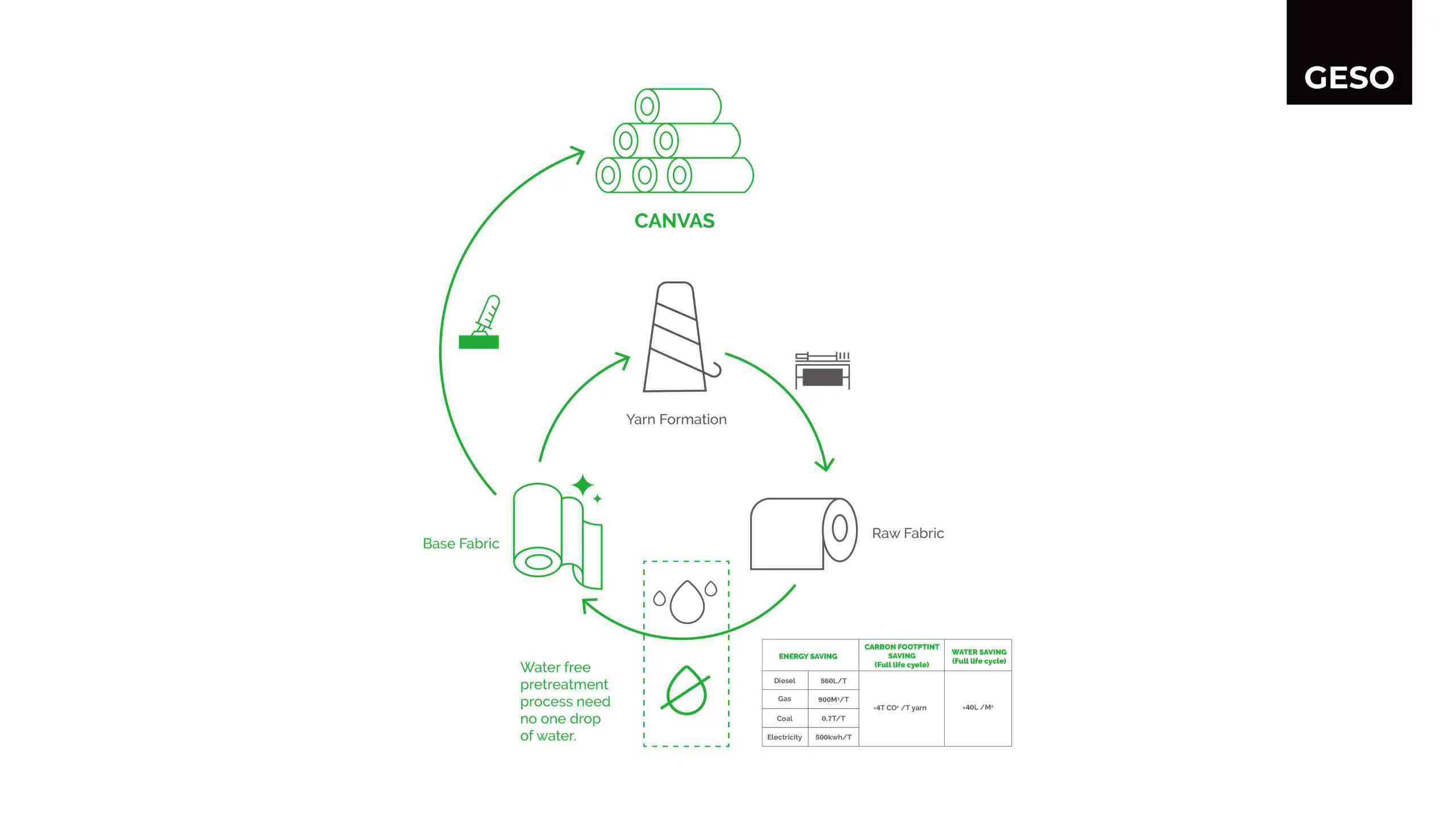

From a canvas industry perspective, traditional canvases are typically made from cotton, linen, or polyester blends, often pre-primed with acrylic resin for better ink adhesion. In digital printing, these materials need to be optimized for machine-fed processes. The wrong canvas can lead to costly downtime, damaged printheads, or subpar output quality. So, what exactly should you look for in a canvas suitable for UVgel printing?

Key Requirements for Canvas in UVgel Printing

1. A Flat Surface for Optimal Print Quality

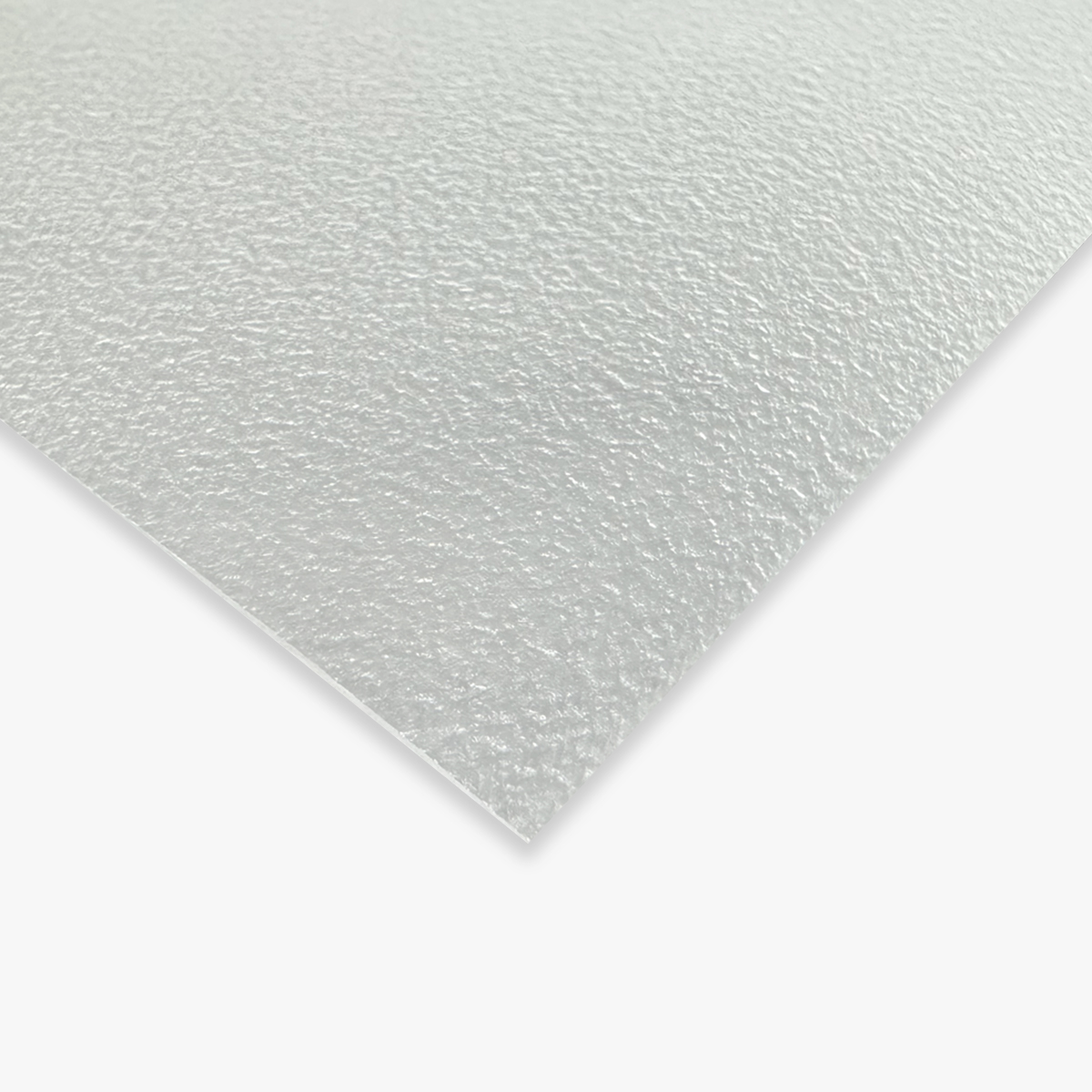

One of the most critical attributes is a perfectly flat surface. In UVgel printing, any irregularities—such as bumps, weaves that are too pronounced, or inconsistent coating—can disrupt the ink deposition process. A flat canvas ensures even ink coverage, preventing banding or color inconsistencies that could ruin your artwork.

Canvas manufacturers in the industry often recommend using machine-coated canvases designed specifically for digital printing. These are engineered with a smooth, uniform primer layer that enhances ink adhesion while maintaining flatness. For instance, archival-grade cotton canvases with a fine weave (around 300-400 gsm) are popular choices because they lie flat without warping under the printer’s vacuum or roller systems. Avoid handmade or stretched canvases that might have subtle undulations; instead, opt for roll-form canvases that can be fed smoothly through the printer.

Pro Tip: Test the flatness by laying the canvas on a level surface—if there is any air pockets or lifts, it might not be the best canvas for UVgel printing.

2. Straight Edges Without Curling to Prevent Machine Damage

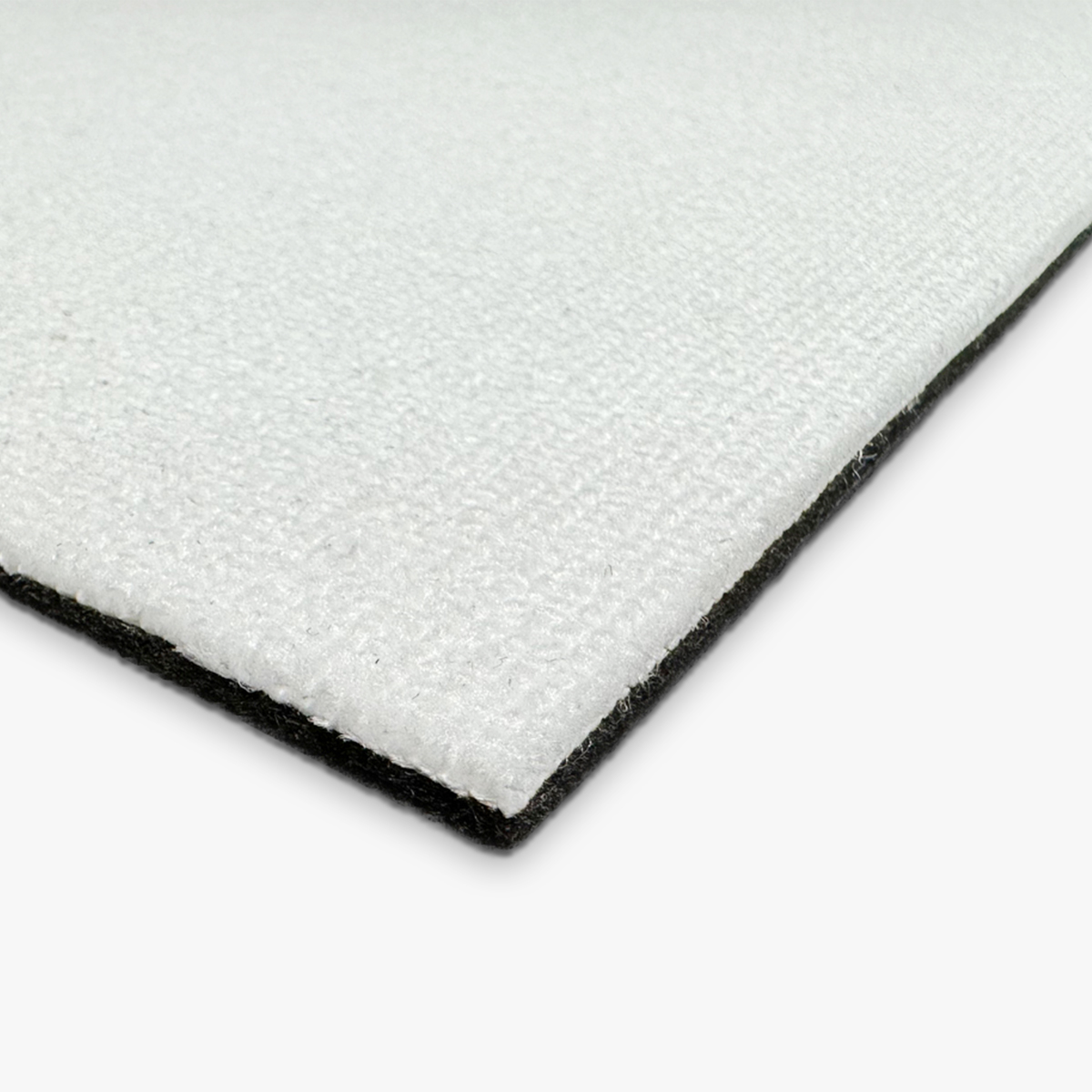

Equally important is ensuring the canvas edges remain straight and free from curling. Curling, often caused by humidity, poor storage, or low-quality materials, can be disastrous in UVgel printing. As the canvas feeds through the machine, curled edges might lift and rub against the printhead, leading to scratches, clogs, or even complete head failure. Repairing or replacing a UVgel printhead can cost thousands of dollars, not to mention the lost production time.

In the digital printing industry, experts advise selecting canvases with reinforced or heat-treated edges to minimize curl. Poly-cotton blends are particularly resistant to environmental factors that cause warping, making them a reliable option for UVgel applications. Additionally, store your canvas rolls in a climate-controlled environment (around 50-60% humidity) and allow them to acclimate before printing. If you’re dealing with persistent curl, consider using edge guides or tensioning systems in your printer setup, but starting with a curl-resistant canvas is the best preventive measure.

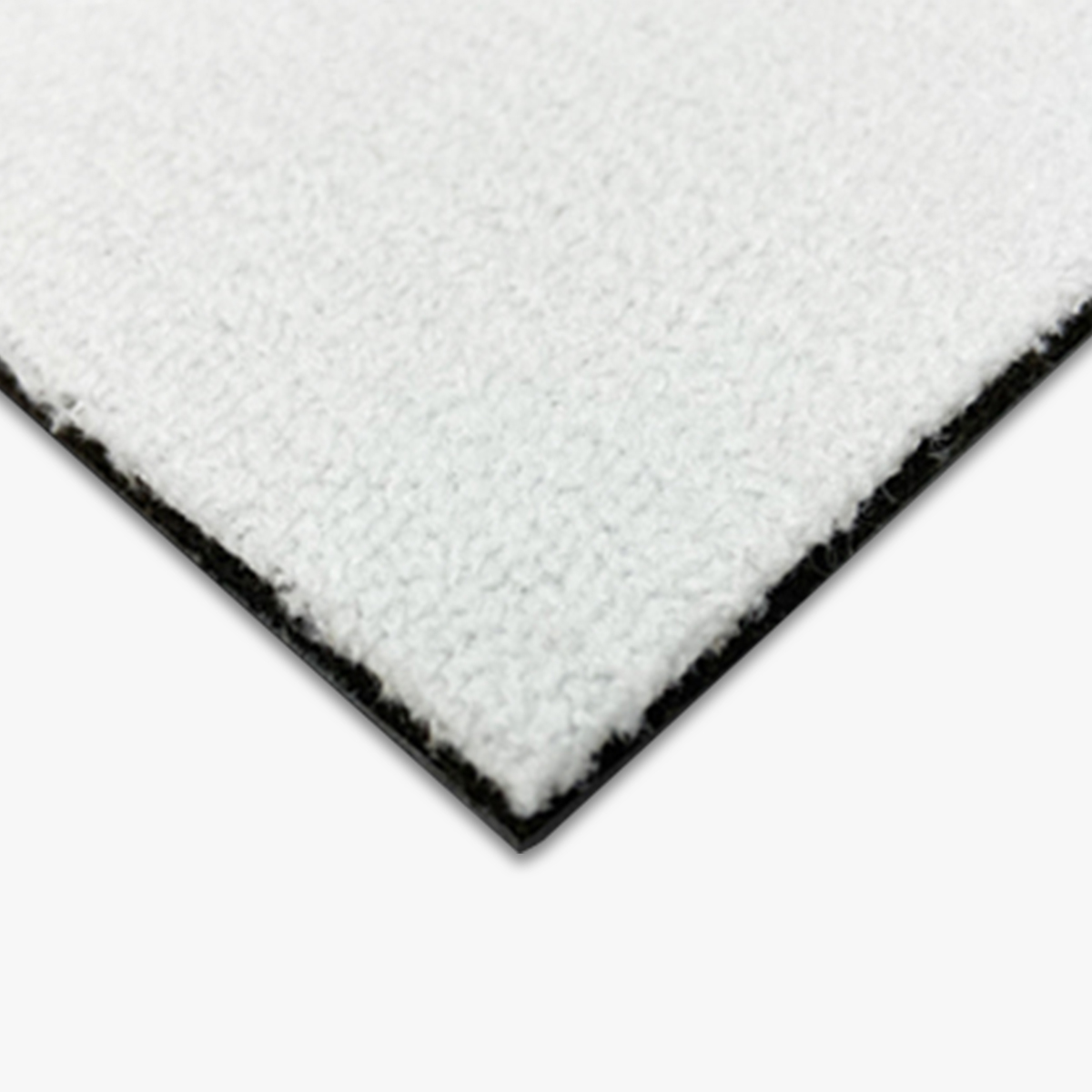

3. Specialized Coating for UVgel Ink Adhesion

The most fundamental requirement is a specialized coating designed specifically for UV or UVgel inks. Standard canvas designed for pigment or dye inks will not work effectively. The coating is engineered to promote strong mechanical adhesion during the instant curing process, control dot gain to prevent bleeding, and ensure consistent curing from the surface down to the substrate. Always choose a canvas explicitly labeled as compatible with UV Inkjet or UVgel printing to avoid issues like poor adhesion, cracking, and washed-out colors.

Additional Considerations for Choosing the Best Canvas for UVgel Printing

Beyond the physical substrate, proper digital setup is crucial:

Manufacturer-Approved Media Profile: Always use the ICC profile provided by the canvas manufacturer for your specific printer model. This ensures correct ink limits, color mapping, and curing settings.

Printer Settings: Utilize the unique layer height control of UVgel printers to adjust ink thickness for desired saturation and texture. Ensure the UV LED curing power is set correctly—perform a “thumb twist” test to verify the ink is fully cured and scratch-resistant.

Why These Features Matter for Your UVgel Projects

Investing in the right canvas not only safeguards your digital printing equipment but also elevates the final product. A flat, non-curling canvas allows for higher print speeds, vibrant colors, and gallery-worthy finishes. Whether you’re printing custom wall art, gallery wraps, or commercial displays, these qualities translate to efficiency and client satisfaction.

In summary, the best canvas for UVgel printing is one that’s engineered for flatness, edge stability, and ink compatibility. By prioritizing these traits, you’ll avoid common pitfalls and unlock the full potential of this innovative technology. If you’re ready to upgrade your canvas selection, explore specialized suppliers in the canvas industry for options tailored to digital printing needs.

Have questions about UVgel printing on canvas or need recommendations? Drop a comment below—we’d love to hear from you!