How Recycled Yarn Canvas Reduce Carbon Footprint?

Blogs 2024-08-12

Introduction

In the rapidly evolving world of sustainable manufacturing, the textile industry faces a critical turning point. With global carbon emissions on the rise and environmental regulations becoming stricter, innovative solutions such as recycled yarn canvas are emerging as true game-changers. In this article, we’ll explore how recycled yarn canvas—especially when produced through advanced water-free techniques—can significantly reduce carbon footprints without compromising quality.

Understanding Recycled Yarn Canvas and Its Sustainable Benefits

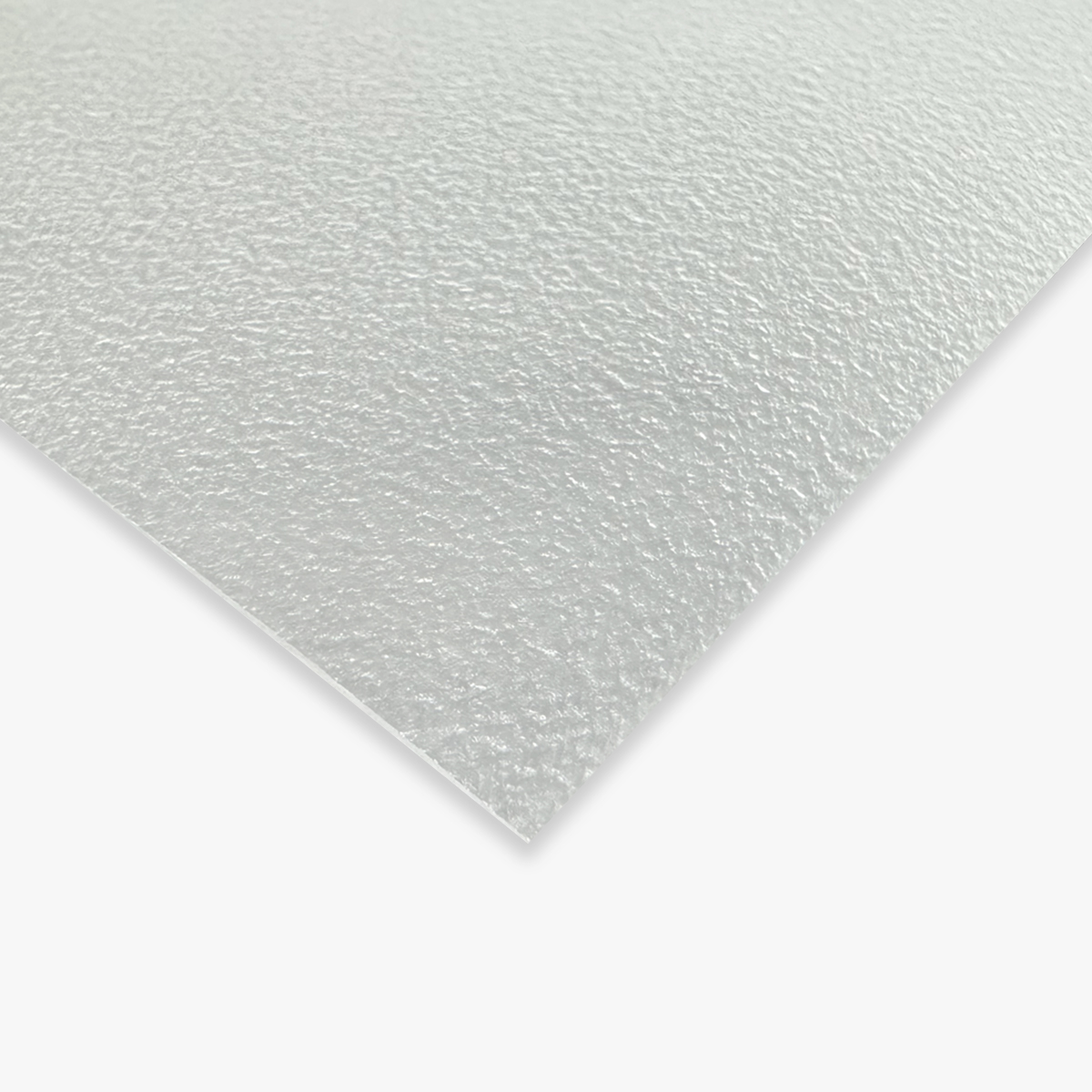

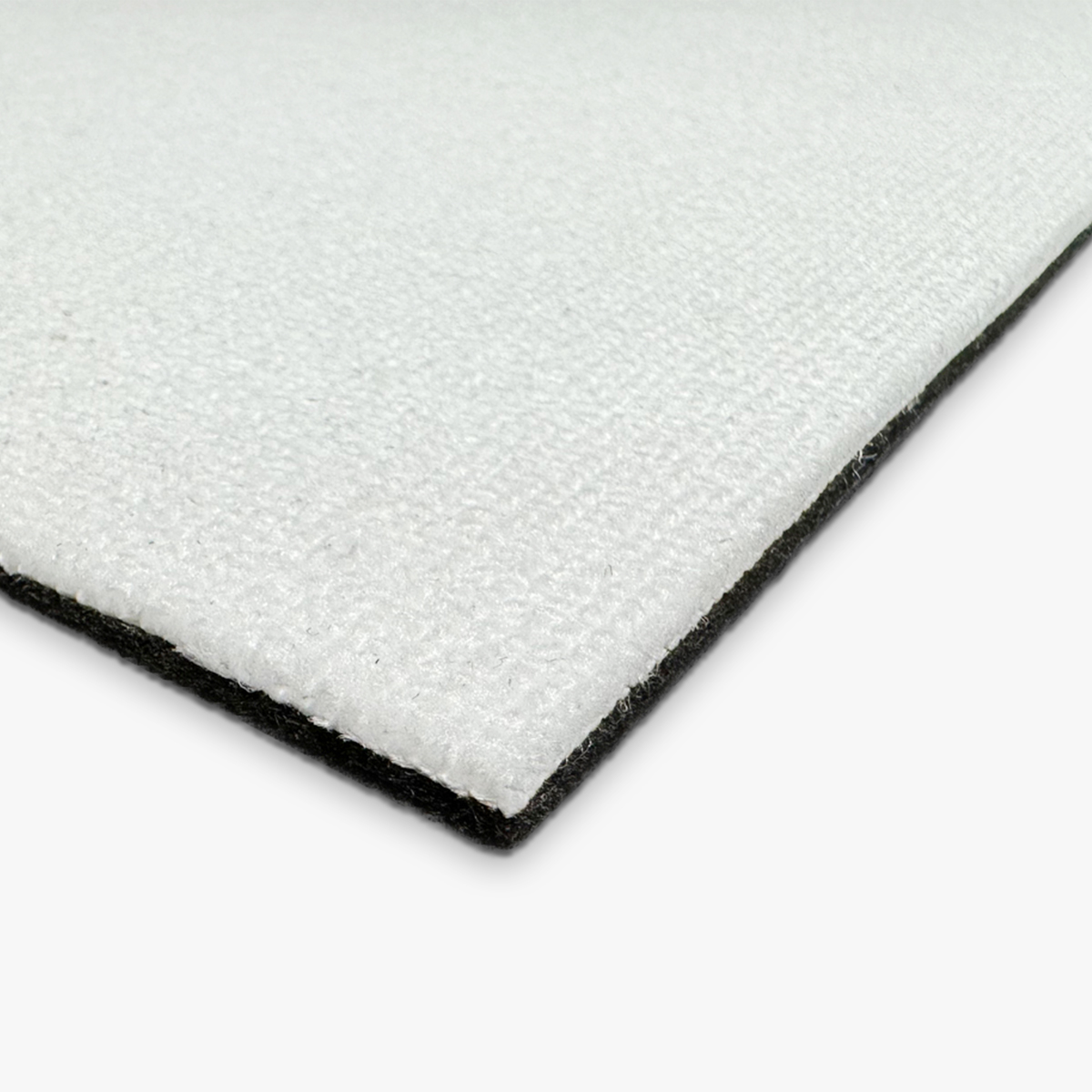

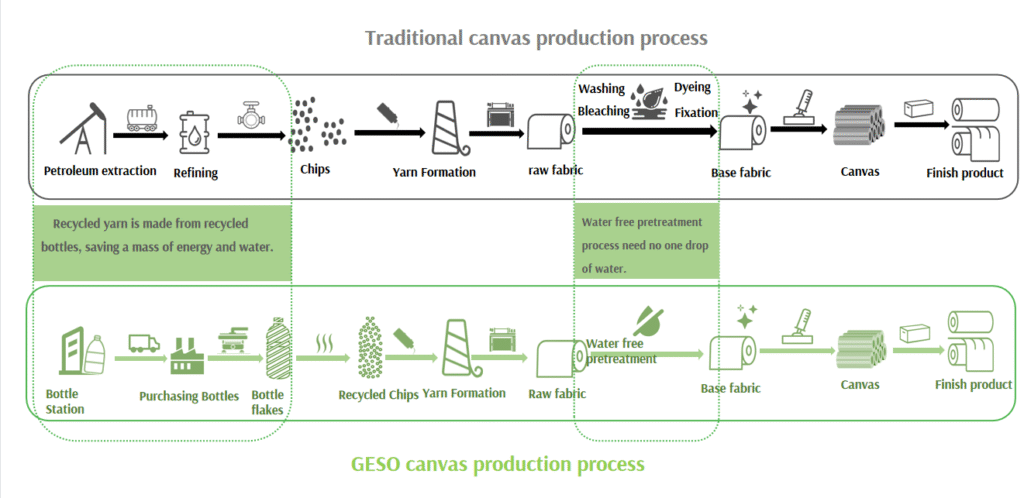

Recycled yarn canvas is made from yarns derived from recycled materials, including post-consumer waste of plastic bottles. This method not only diverts waste from landfills but also reduces the demand for virgin resources, which typically involve energy-intensive extraction processes. Conventional canvas production relies heavily on water, energy, and chemicals during dyeing, pretreatment, and finishing—all major contributors to greenhouse gas emissions.

What distinguishes modern recycled yarn canvas is its foundation in circular economy principles. By reusing materials, manufacturers can create closed-loop production cycles that drastically lower environmental impact. At GESO, for example, our recycled yarn canvas begins with sustainable sourcing—transforming recycled bottles into bottle flakes, then slicing flakes to even smaller chips. Later on yarns are formed with recycled chips, these chips can be woven into high-quality, durable canvas with our advanced water-free pretreatment. This approach goes beyond recycling; it involves rethinking the entire product life-cycle to maximize efficiency and minimize waste.

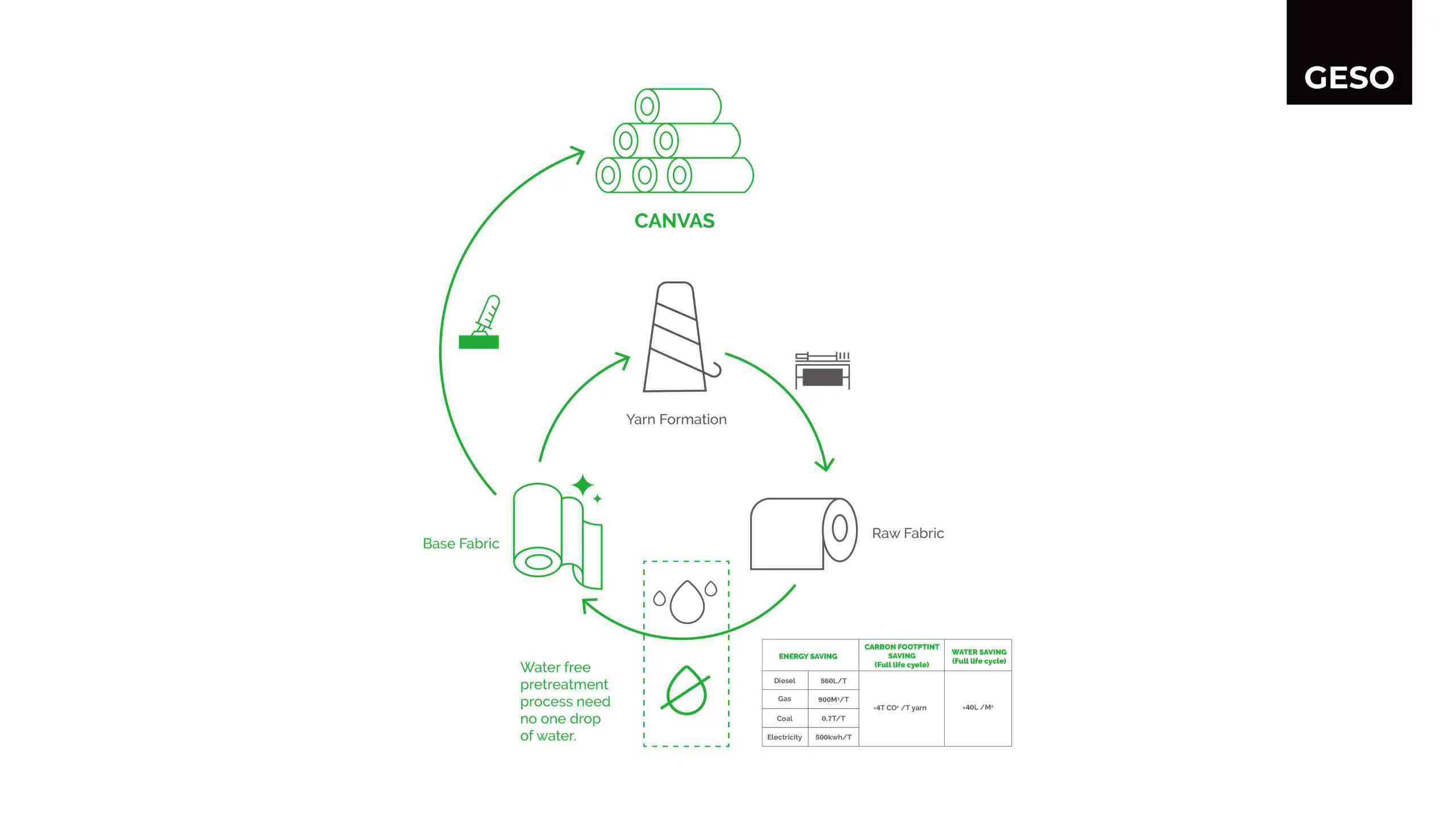

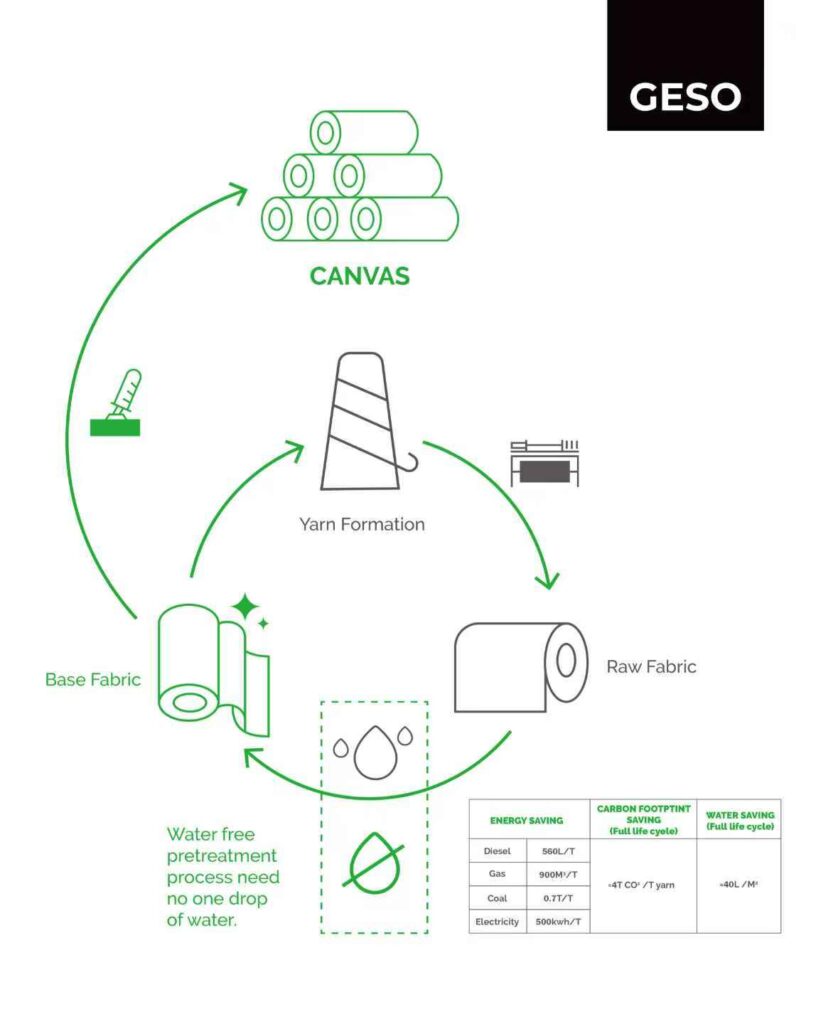

The Power of Water-Free Pretreatment in Recycled Yarn Canvas Production

One of the most revolutionary aspects of our recycled yarn canvas is the adoption of water-free pretreatment processes. Traditional textile pretreatment—preparing fabrics through washing, dyeing, bleaching and fixation—typically requires enormous volumes of water, often leading to pollution and high energy use for heating and treatment. In contrast, our water-free pretreatment eliminates the need for even a single drop of water in the stage where raw fabric turns into base fabric, relying instead on advanced mechanical and chemical innovations that achieve the same results with far less environmental strain.

This shift to water-free technology in recycled yarn canvas production directly addresses key sustainability challenges. By avoiding water-intensive steps, we not only conserve precious resources but also cut down on the energy required to pump, heat, and purify water. The result? A cleaner, more efficient process that aligns with global goals like the UN’s Sustainable Development Goals for responsible consumption and production.

Quantifying the Impact: Energy, Carbon, and Water Savings with Recycled Yarn Canvas

To fully grasp how recycled yarn canvas reduces carbon footprints, let’s look at the data from our production metrics. These figures are based on full lifecycle assessments, comparing our recycled yarn canvas processes to conventional methods:

Energy Savings: By optimizing yarn formation and fabric weaving in recycled yarn canvas, we achieve substantial reductions in energy consumption. For every ton of yarn produced:

- Diesel: 560 liters saved

- Gas: 900 cubic meters saved

- Coal: 0.7 tons saved

- Electricity: 500 kWh saved

These savings stem from streamlined operations, such as efficient yarn spinning and reduced machinery downtime, all while using recycled materials that require less processing than raw fibers.

Carbon Footprint Reduction: Across the full lifecycle—from raw material sourcing to end-product disposal—recycled yarn canvas slashes emissions by approximately 4 tons of CO₂ per ton of yarn. This is a direct outcome of lower energy use and the avoidance of carbon-heavy extraction processes for new materials. In an industry where textiles account for about 10% of global carbon emissions, adopting recycled yarn canvas can make a measurable difference in combating climate change.

Water Savings: The water-free pretreatment in our recycled yarn canvas process delivers an impressive 40 liters saved per square meter of fabric over the full lifecycle. This is crucial in regions facing water scarcity, where traditional textile production can consume up to 200 liters per meter.

These metrics aren’t just numbers; they represent real-world progress toward net-zero goals. By choosing recycled yarn canvas, businesses in sectors like fashion, upholstery, and industrial applications can lower their Scope 3 emissions (those from supply chains) while enhancing their sustainability credentials.

Broader Benefits and Real-World Applications of Recycled Yarn Canvas

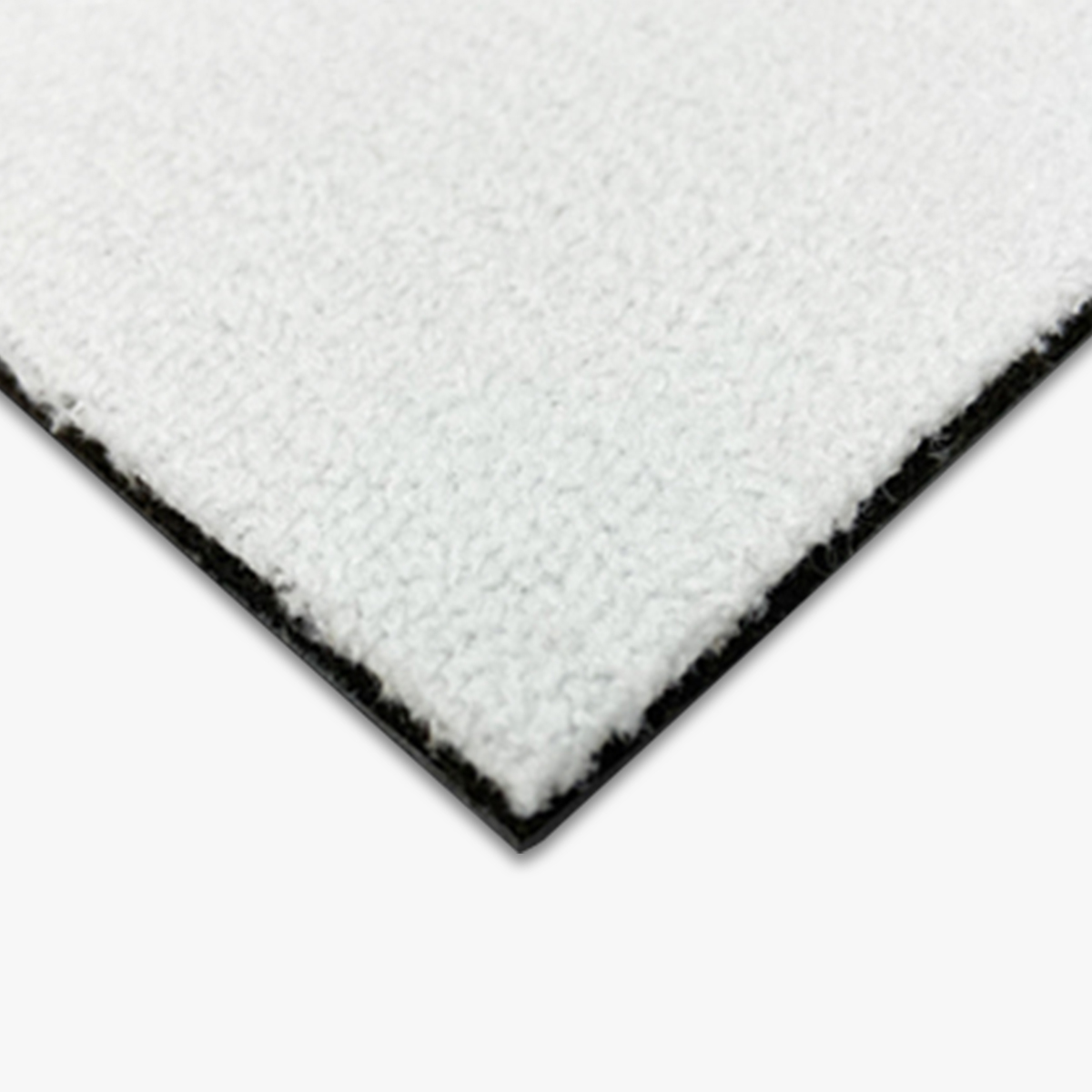

Beyond the environmental wins, recycled yarn canvas offers practical advantages. It’s durable, versatile, and performs just as well as traditional canvas, making it ideal for products like tents, bags, and apparel. Companies adopting recycled yarn canvas often see cost savings over time due to reduced resource inputs

From a sustainability perspective, scaling up recycled yarn canvas production could transform the industry. By diverting post-consumer plastic bottles and textile waste from landfills, its production significantly conserves resources and reduces the pollution associated with virgin material extraction. This sustainable fabric is then ingeniously repurposed into a robust and durable canvas, finding critical use in a wide array of products. From heavy-duty tote bags and stylish footwear to innovative interior design elements like acoustic panels and upholstery, recycled yarn canvas demonstrates that environmental responsibility does not compromise quality or functionality. Its adoption by industries ranging from fashion and art to architecture and manufacturing showcases a tangible shift towards a circular economy, proving that waste can be transformed into valuable, long-lasting, and practical goods for everyday life.

Conclusion: Why Choose Recycled Yarn Canvas?

In conclusion, recycled yarn canvas represents a powerful tool for reducing the carbon footprint of the canvas industry. Through water-free processing and efficient resource use, it delivers measurable savings in energy, water, and emissions. At GESO, we are dedicated to advancing these technologies, demonstrating that high-quality materials and environmental stewardship can coexist.

If you operate in the canvas industry or are exploring sustainable alternatives, consider integrating recycled yarn canvas into your supply chain. It’s a strategic business decision that benefits both the planet and your bottom line. Together, we can weave a greener future—starting with recycled yarn canvas.